The release of chlorine gas into the atmosphere poses a threat to all living things. A gas leak, especially in facilities located near residential areas, is a risky situation for human health. For this reason, in order to prevent potential problems, and because it is a matter considered by environmental legislation and local administrations, Gas Chlorine Neutralization systems are applied to these facilities.

Polypropylene, polyethylene, etc. Systems we design using plastic raw materials;

-Ventilation pipelines,

-Acid Fan,

-Dosing System,

-Autonomous control system,

designed and manufactured with the aim of being used safely for many years with high efficiency and low energy consumption.

Advantages of being Polypropylene, Polyethylene, PVC;

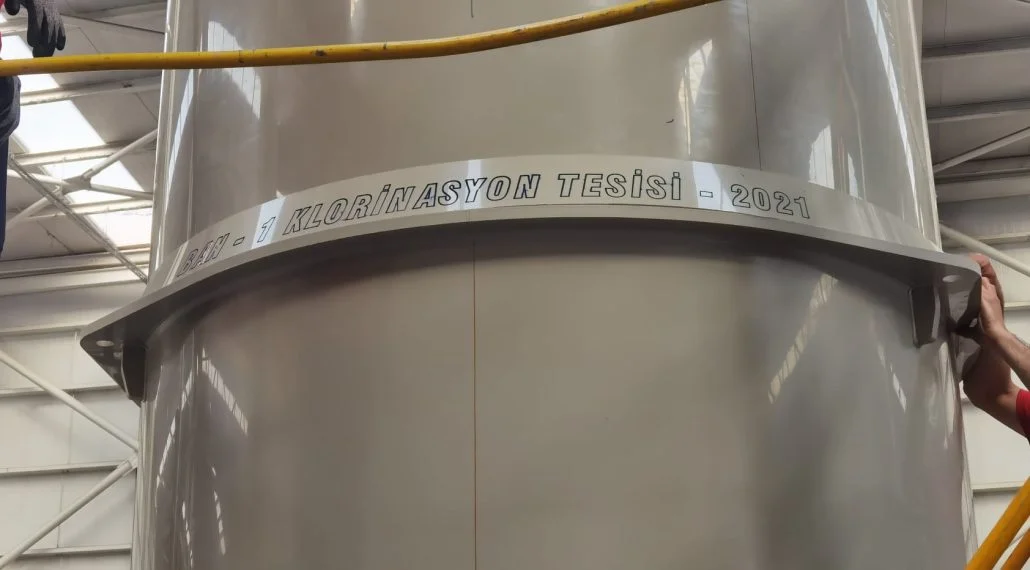

Scrubber systems, specially designed according to the needs of the process and your capacity, produced by selecting materials and equipment using scientific methods, are installed and commissioned on site.

In our Frequently Asked Questions section, we've tried to answer the most common questions our customers have about our tank manufacturing services. However, if you need more information or have a specific question, please don't hesitate to contact us. Our expert team is here to help you in the best way possible.

Gas scrubbing systems are equipment used to remove pollutants, particles, and gases generated in industrial processes. These systems typically bring a gas stream into contact with a liquid solution. Upon contact, the liquid dissolves or absorbs the pollutants in the gas, releasing clean gas into the air. Gas scrubbing systems are critical for controlling industrial emissions and complying with environmental regulations.

Odor removal systems are used to reduce or eliminate unwanted odors in industrial and commercial facilities. These systems typically work by addressing the source of bad odors through chemical, biological, or physical processes. Chemical scrubbers, biological filters, or activated carbon filters are common components of odor removal systems. These systems are important for protecting employee health and ensuring environmental compliance.

Regular maintenance of gas scrubbing and odor removal systems is critical to ensuring the system operates efficiently and safely. Maintenance typically includes cleaning system components, replacing filters, checking fluid levels, and assessing the overall condition of the system. The frequency of maintenance may vary depending on the type of system and the intensity of use, but regular maintenance is generally recommended. Periodic checks and maintenance performed by qualified technicians ensure the longevity and continued performance of the systems.